Brand Name: yongda

Model Number: WZP-60

Place of Origin: Henan, China (Mainland)

After-sales Service Provided: Engineers available to service machinery overseas

name: bolts ends forging

usage: forging bolts,nuts, steel bars

Input current: 4-60A

Power: adjustable from 3 KW to 35 KW

Core parts: IGBT modules

accessories: induction coils,foot switch

heating capacity: 1.5kg/min, 1200 degree

frequency: 15-30KHZ

coils: easy to change

warranty: one year free replacement spare parts

3-4 piece at a time induction heating bolts ends forging WZP-60

Technial parameters of WZP-60 bolts ends forging machine

Model |

WZP-60 |

Input Voltage |

Three phase 380 V +/-10% 50-60HZ |

Input current |

3-60A |

Output power |

35kw (power adjustable 3-35KW) |

Oscillation frequency |

15-30KHZ |

Cooling water pressure |

0.1-0.2MPA |

Size (L*W*H) |

Generator 590×330×650mm Transformer 500×360×455mm |

Net Weight |

Generator 41KG transformer 37kgs |

Cooling water temperature |

Below 50 degree |

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

WZP-40 |

320-420V |

2-40A |

15-30KHZ |

0.1MPA |

WZP-60 |

320-420V |

3-60A |

15-30KHZ |

0.2MPA |

WZP-90 |

320-420V |

4-90A |

15-30KHZ |

0.3MPA |

WZP-120 |

320-420V |

6-120A |

15-30KHZ |

0.3MPA |

WZP-160 |

320-420V |

6-160A |

15-30KHZ |

0.3MPA |

WZP-200 |

320-420V |

6-200A |

15-30KHZ |

0.3MPA |

WZP-300 |

320-420V |

6-300A |

15-30KHZ |

0.3MPA |

WZP-400 |

320-420V |

6-400A |

8-15KHZ |

0.3MPA |

WZP-500 |

320-420V |

6-500A |

8-15KHZ |

0.3MPA |

Features of induction bolt heat machine :

1, small size, light weight, easy installation, easy operation.

2, high efficiency, saving energy obviously, high-frequency energy-saving equipment than the traditional 60%

3, safe and reliable, no million-volt high-pressure, very safe for the operator.

4, the frequency bandwidth to meet the different parts of brazing, heat treatment, forging before heating.

5, a unique cooling system, ensure that the equipment 24 hours of continuous work

Working onsite of induction bolts ends forging machine

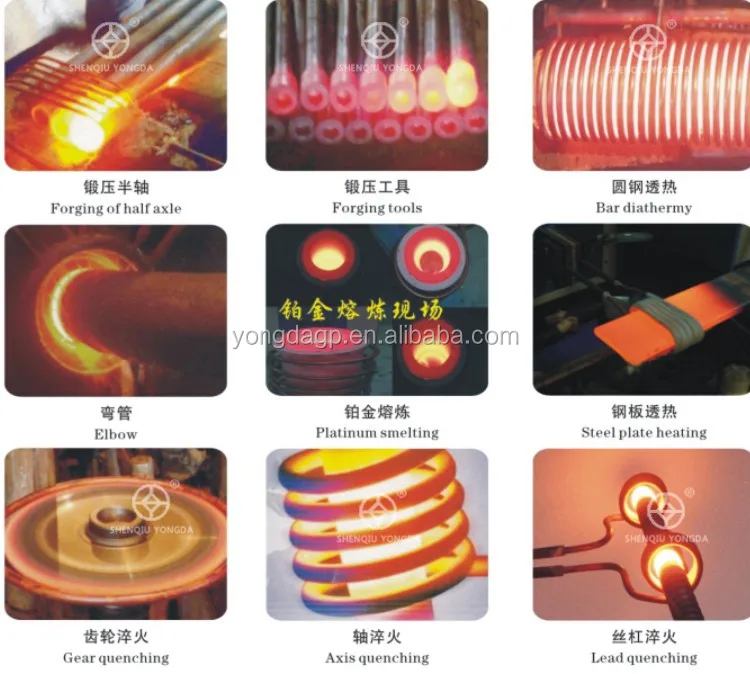

Applications of induction heating machine

First, the application of heating equipment

1, through thermoforming all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist drill of hot forging, hot rolling, metal annealing. Such as: tensile steel; wire, nail wire heating; stainless steel annealed, rose type.

2, heat treatment various types of hardware tools, electric, hydraulic, pneumatic components, automotive, motorcycle parts and other mechanical parts of the surface of the metal, the hole, partial or total quenching. Such as: hammer, knife, scissors, pliers and all kinds of shafts, cams, sprockets, gears, valves, ball stud, a large machine tool guide, ductile iron quenching.

3, various types of brazing carbide blade, turning, milling, planing, reamer, diamond saw blade, serrated welding; grinding, drilling, cutting welding; brass, copper, stainless steel pot, etc. hybrid welding of metallic materials.

4, metal melting: melting gold, silver and copper.

5, other areas of plastic pipe heating cable, heating wire coating; food, beverage, pharmaceutical industry, the use of aluminum foil.

We are in induction heating industry exhibition

Warranty: one year free replacement spare parts

After -sale service: provide long-term technical support

Install: When you receive the machine, can easy install the machine based on our installing drawings, sketch.

Customer need prepare water hose, electric, build a water pool or welding water tank, or buy a closed cooling tower, or industrial chiller. We aslo can provide if you needed. Such as CNC hardening machine tool ,automatic feeding machine, infrared thermometer, industrial chiller etc. These auxiliary machines are optional.

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu County, Zhoukou City. We professionally dedicated to Research & Development,production of high frequency induction heating machine, medium frequency induction heating equipment,supersonic frequency induction heating machine,induction forging machine, induction hardening machine, adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004. Up to now, we has 83 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions. We have international trade office in zhengzhou. East to international airport (CGO), besides, high way, high speed rail,transport is very convenient.

What’s your MOQ? |

Any quantity of machine will be accepted. MOQ:1 Set |

Which place your factory is located? |

We are located in Shenqiu County, Zhoukou city, Henan Province ,China |

How far from Beijing? I think it is more closer to Shanghai |

Our factory is near both and Shanghai. We have office in Zhengzhou, we can pick up you at Zhengzhou CGO airport,and then to our factory via expressway about two hours. |

We need to see some more videos for production line and also pictures of your factory, water drawing and panel drawing |

Well, we have many videos show our customer’s machine working scene(Various of applications: forging,hardening, brazing, shrink fitting, melting and hot coating etc. According to your work piece processing requirements,) send you the corresponding video link or send by email. 2. Yes, we can provide you factory pictures and machine water connection and control panel details. |

Do you have quality certifications? |

Yes, we got the ISO9001:2000 International quality management system certification in August,2001, |

How do you packing the machines? |

Standard export wooden cases(plywood) Usually every set machine will be used two wooden cases: one for packing induction heating generator, one for packing transformer. Inside will be filled with plastic foam for waterproof and shockproof |

More questions….? |

Updating… |

More information about bolts forging induction heating machine,welcome to contact us !